Roof fans

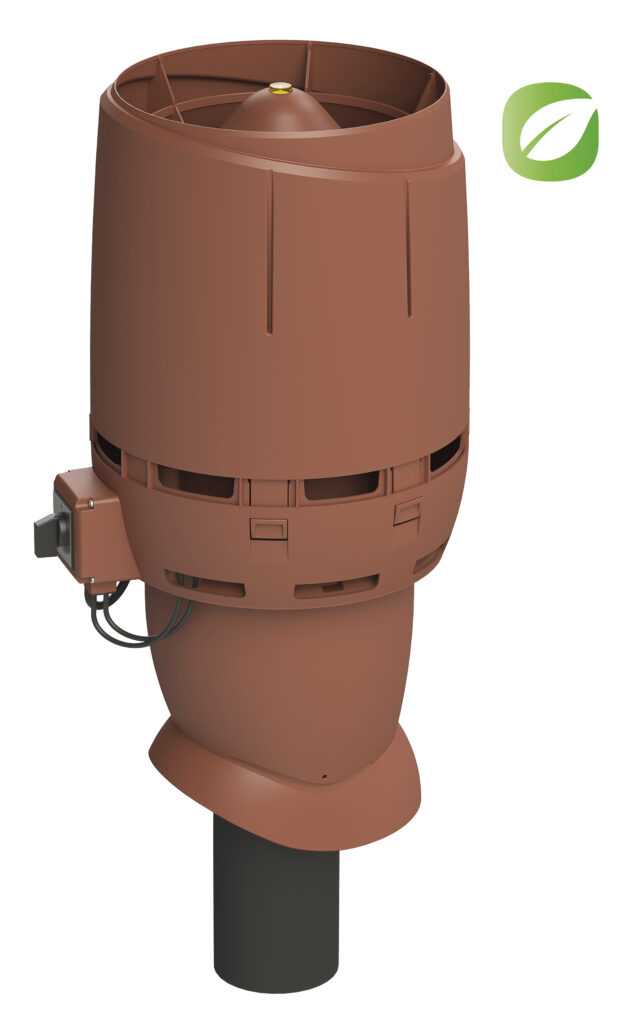

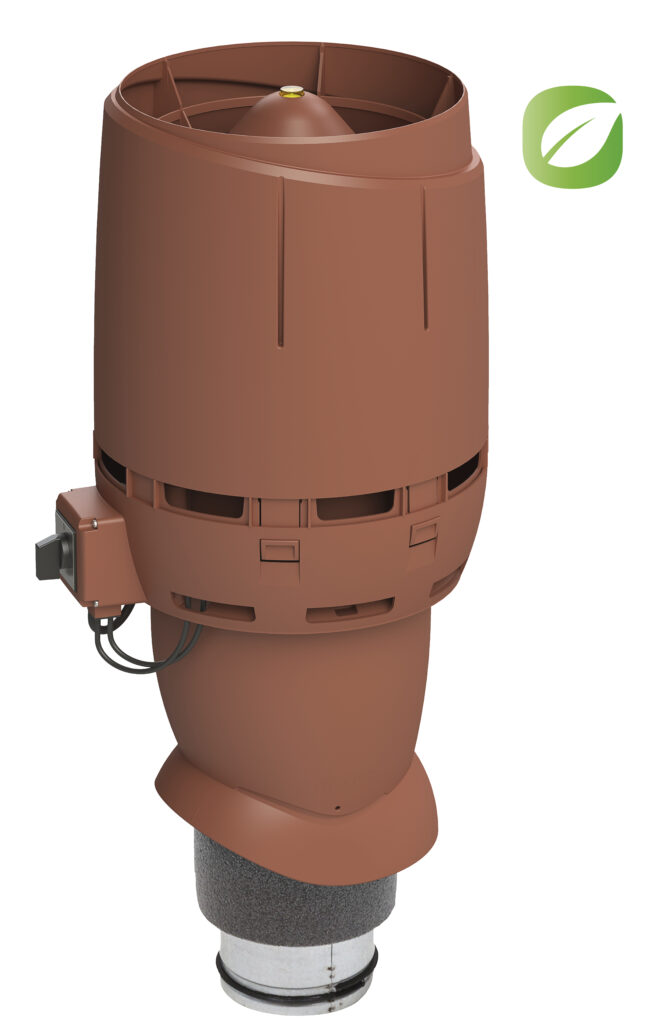

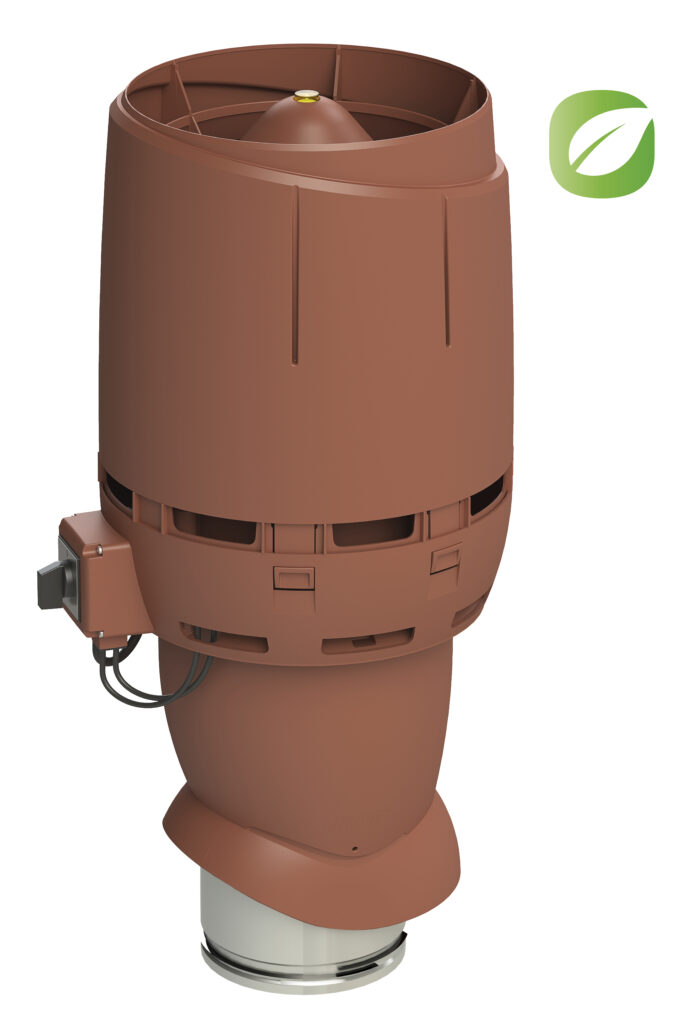

VILPE’s high-quality roof fans effectively remove dirty and stale air from the building. Intended for Mechanical Extraction Ventilation (MEV), our fans come in a range of sizes and can be used for different purposes and building types. For example, VILPE roof fans are compatible with building automation and control systems such as motorless cooker hoods--helping you remove smells and moisture from the kitchen whilst reducing annoying noise from the cooker hood itself. Please note, however, that if you have an older model roof fan such as the VILPE E roof fan with an AC (alternating current) motor, you can manually control it with either a cooker hood suitable for AC roof fans or with a VILPE control panel. This product range also includes the VILPE ECo Ideal Wireless Automatic Control System, an automated system which continuously adjusts the required level of ventilation according to the prevailing air quality inside a building. Wireless sensors measure the relative humidity (RH) and carbon dioxide (CO2) levels in the air, and send this information wirelessly to the control unit. The roof fan’s effectiveness is then adjusted to ensure good air quality without the unnecessary use of excessive energy. It is an easy and affordable way to turn a passive ventilation system into a demand-controlled ventilation system that saves both energy and money. Learn more about the VILPE ECo Ideal Wireless system, and find the right product for your needs below.

Read the FAQ

Read the FAQ