VILPE examined the carbon footprint of the IO product family

Carbon Footprint calculations for all six VILPE IO product models were executed in 2022 by Ramboll, an independent outside agency. The reason for carrying out the carbon footprint study was to gain reliable information of the global warming potentials of the IO products and how the impacts are formed.

”The gained results are used to improve VILPE’s operation, and to provide reliable information of the product carbon footprint to the stakeholders”, says Anastasia Parfenova, the operative purchaser and environmental assistant of VILPE.

The study follows the standardized methods of Life Cycle Assessment (LCA) and guidelines of the standard ISO 14067:2018 Carbon footprint of products. Carbon footprint and LCA refer to the total of greenhouse gas emissions caused during the life cycle of a product, from raw material supply to disposal.

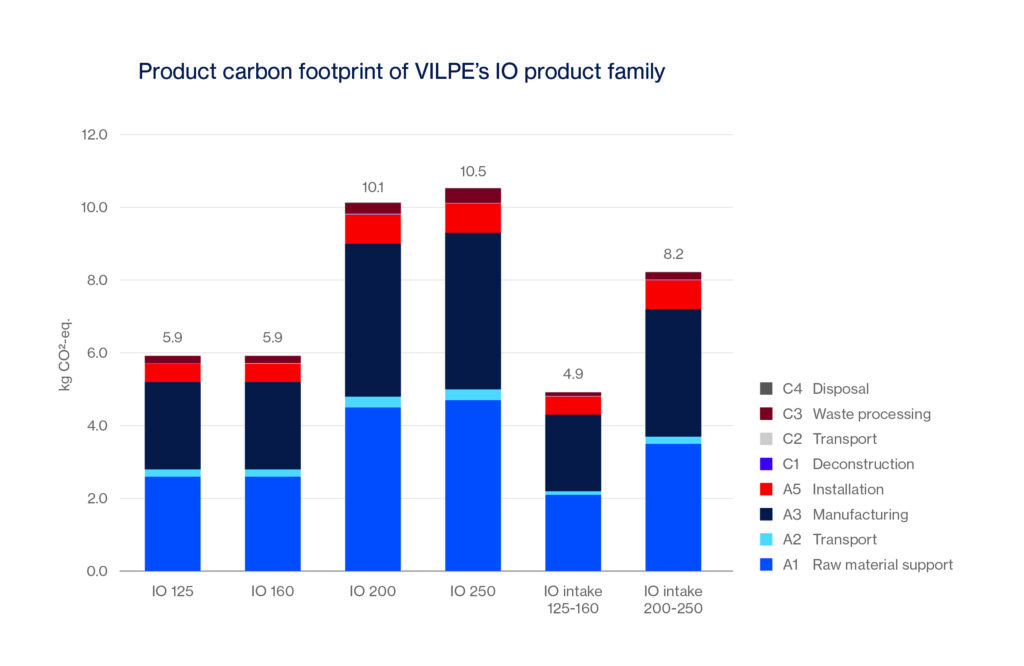

Results are calculated per one piece of product in kilograms of CO2 equivalent (kg CO2-eq).

Most of the emissions come from manufacturing and raw material supply

The IO products are made of similar raw materials at the same production facility but vary in size. The study indicates that product carbon footprints of VILPE IO product family vary from 4.9 to 10.5 carbon dioxide equivalent.

42–45 % of the IO products’ emissions are related to the raw material supply, and manufacturing emissions at VILPE’s production facility in Mustasaari form approximately 41–42 % of the emissions. Installation stage forms 8–11 % of the product carbon footprint, whereas the remaining calculated life cycle stages are only 5–7 %.

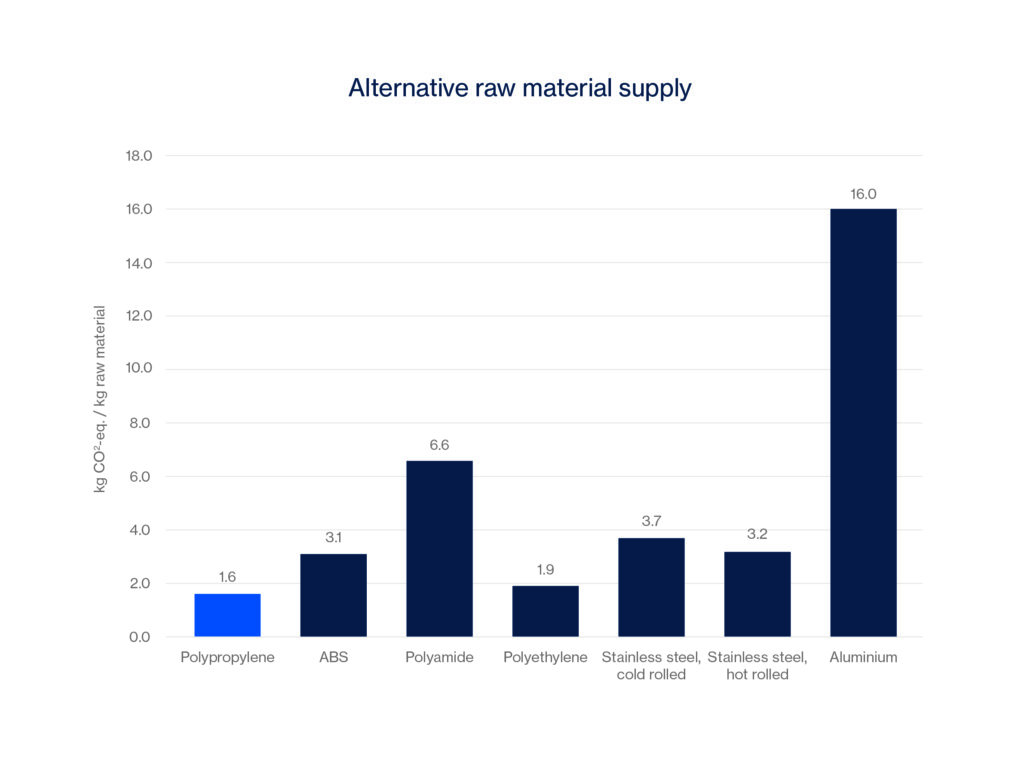

Most of the raw material supply related emissions come from polypropylene, the main raw material used in the IO products. Polypropylene’s emissions are, however, lower compared to other raw material alternatives – for example, one kilogram of polypropylene is 1.6 kg CO2-eq, when one kilogram of aluminium is 16 kg CO2-eq (see the following table).

IO products made of polypropylene are also long-lasting, and VILPE provides its products a 20-year technical warranty and a 10-year colour warranty.

Ground source heat system reduces emissions in the future

Most manufacturing emissions come from electricity consumption in VILPE’s factory. The data for the study was collected in 2021, while installation of ground source heat pump system to VILPE’s factory was still in progress.

“Therefore, these official calculations were done with data predating the new heating system. In future calculations the factory CO2 emissions will be even lower”, Parfenova says.

The ground source heat pump system began operations in autumn 2021. Combined, both the ground source heat pump cooling and heating systems allow VILPE to efficiently cool its factory buildings, production machinery and molds using ground source energy, with some of the heat from this process being then stored in the bedrock beneath the factory to then be used to help heat the buildings during the colder months of the year.