How an Expert Prepares Your VILPE Sense Project Plan

Are you interested in adding VILPE Sense solutions into your project? VILPE’s experts are here to assist you: they will provide a comprehensive plan indicating where VILPE Sense products should be installed in your building. This article outlines how the planning process is carried out in practice.

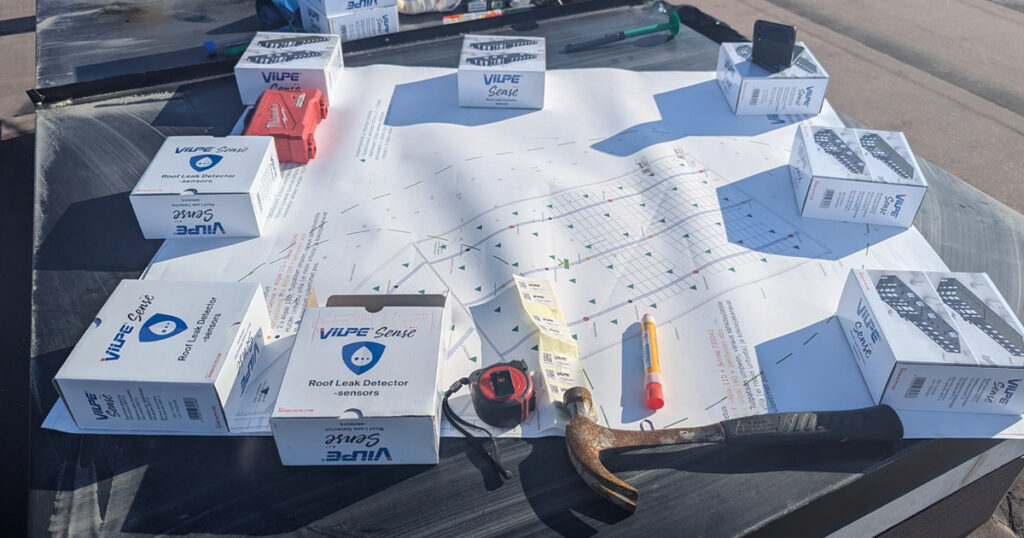

A VILPE expert begins designing the placement of VILPE Sense products once they have received the roofing and/or structural drawings of the project. This article features VILPE’s new premises in Vantaa, Finland as an example.

The building will have both VILPE Sense humidity control and leak detection. The project’s complexity is heightened by the presence of both a green roof and solar panels. VILPE’s Product Manager Kimmo Kujala started the planning by studying the roofing layout.

“Placing the Sense products on the roof is not rocket science. The plan was easy to draft,” Kujala says.

Planning VILPE Sense Humidity Control

When planning VILPE Sense moisture management, it is essential to ensure proper air movement within the structures and adequate intake air supply. In new builds, there may be opportunities to influence the structural design. For existing buildings, experts assess whether current ventilation systems can be utilized. The positioning of Sense roof fans considers, for instance, the location of negative pressure vents.

The Vantaa premises have varying roof structures, each designed with different approaches for the Sense products. For example, the warehouse roof draws intake air from the edges and through negative pressure fans along the centerline. The roof fans are positioned between the edge and the centerline. The office section has a ventilated attic space, where the roof fan is in the middle, receiving intake air from the building’s edges.

The placement of sensors varies across different roof sections. On a flat roof, the indoor control sensor is placed on top of the insulation within a negative pressure equipped with a roof fan. In a ventilated attic space, the indoor control sensor is near an exhaust ventilation point, such as in a roof truss.

For both roof sections, outdoor control sensors were installed under the eaves, in places where they are shielded from direct sunlight and do not get buried under snow in winter. Mobile base stations are installed where they can effectively receive signals from both the Sense sensors and exhaust fans.

Planning VILPE Sense Leak Detectors

For VILPE Sense leak detectors, the standard practice is to install sensors within the insulation layer approximately 4-5 meters apart (10 sensors per 200 square meters). For this project, they were designed to monitor the entire roof surface.

The Vantaa site is a new building, so the VILPE Sense leak detectors were installed during the construction phase, making it easy to set them up before the green roof and solar panels were installed.

The Importance of Monitoring Green Roofs

Continuous monitoring and leak prevention are critical in cases like VILPE’s Vantaa premises, where there is a green roof and solar panels.

“It’s challenging to locate a potential leak under a green roof or solar panels. Repairs are also costly, as soil or panels need to be removed before the roof can be accessed,” Kujala explains.

Saving Time and Money

Moisture accumulated in structures during construction can lead to future problems. To prevent potential damage, VILPE Sense monitors the structures to see if moisture is removed.

Leak detectors help locate any potential leaks, while the humidity control optimizes ventilation in the roof structure and ensures moisture is removed. This helps prevent moisture damage. With VILPE Sense, property maintenance becomes significantly easier. Moisture damage is minimized as the system alerts users when humidity levels rise.

Interested in saving time and money with VILPE Sense? Contact us, and our experts will create a plan for your project.