| Duct size | 250 Ø |

|---|

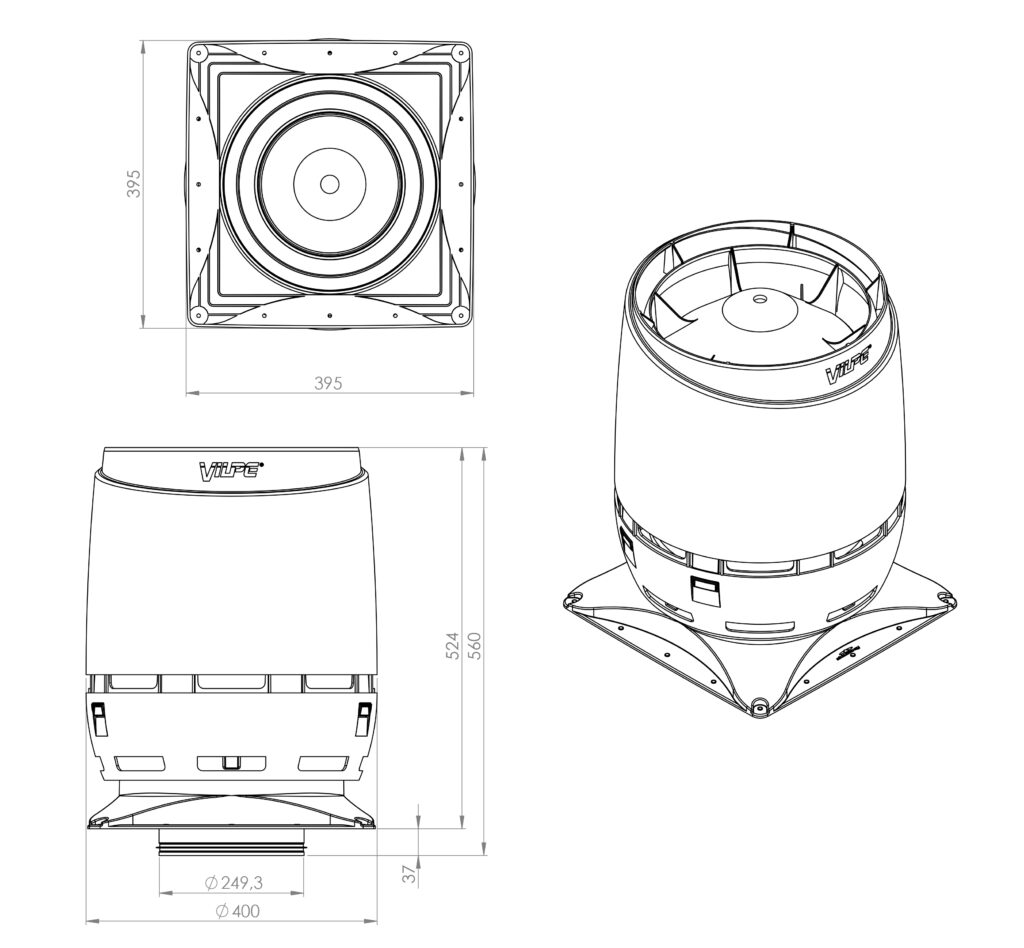

250S FLOW Exhaust Vent 400 X 400

Description: Exhaust vent for a flat surface with FLOW cowl.

Dimensions: Duct size Ø 250 mm; installation set 400 x 400 mm, installation area must be at least the same size.

Contents: Exhaust vent, installation set, adapter and screws.

Share product page

Download CAD Models

Materials & Installation

Send document by email

Videos

Product categories: Exhaust ventilation pipes, S-Series exhausts